Swedish green cement startup Cemvision has raised €10 million in seed funding to further develop their breakthrough technology that turns industrial waste into climate-friendly cement. Their innovative process helps solve two pressing issues – reducing carbon emissions from cement production and giving valuable new life to industrial byproducts.

Traditional cement manufacturing is a major source of CO2, responsible for around 8% of global emissions. Cemvision has invented a cleaner way of making cement that uses residues from other industries like steel and mining instead of virgin limestone. “Our cement releases up to 95% less carbon compared to standard methods while maintaining equal strength and potentially faster drying times,” explains CEO Oscar Hållén.

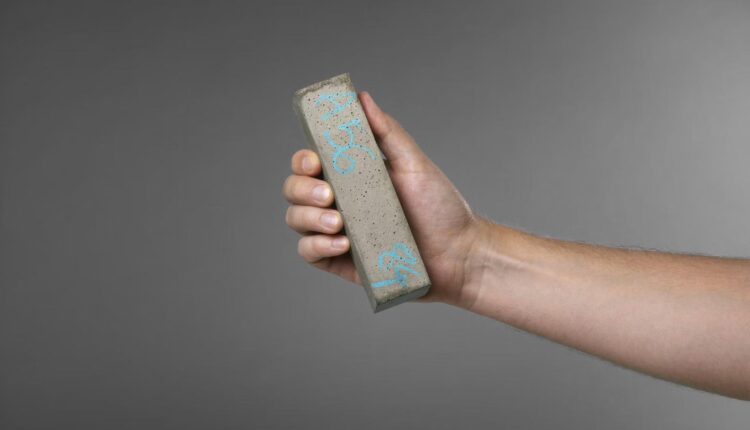

By exploiting certain industrial byproducts like steel slag, Cemvision’s technique sidesteps the CO2-heavy process of breaking down limestone in high-heat kilns. They also use renewable biofuels or green electricity for manufacturing, significantly reducing the carbon impact. As their small demonstration plant in Poland began production in mid-2023, this funding will help scale up and commercialize the technology.

The €10 million injection is the largest seed round ever for a green cement startup and a sign that Cemvision is poised for growth. Plans include refining their patented process, securing new customers like initial partner LKAB, and expanding the talented team. With looming regulations like the EU Carbon Border Adjustment Mechanism pressing for solutions, their climate-friendly cement is well-positioned to play a leading role.

This investment will propel Cemvision’s mission to transform the 400 billion dollar global cement industry towards sustainability. By diverting waste streams into new purpose and eliminating emissions, their innovation marks an important step in the race towards a low-carbon built environment.